Implementation and standardization of the SCADA iFIX system in Waterworks in Racibórz

Implementation of GE Digital products in Wodociągi Raciborskie (Waterworks in Raciborz, Poland) - Case Study (VIDEO)

Implementations of SCADA systems in industrial plants often take place over several (even a dozen or so!) years. Independent installations appear, sometimes even presenting the same variables (although usually in different perspectives). This can cause information (and IT) chaos, and above all, adversely affect the productivity of the industrial plant and its KPIs, as well as unnecessarily extend the process of training and onboarding new employees.

Creating applications in such a decentralized way is quite common in the so-called public sector (although, as practice shows - not only!), where often each installation is a separate tender procedure. Hence... different systems of the same type can be implemented, and if the same software is already implemented, it is done by different contractors. Every experienced engineer knows that coding is like handwriting - it's hard to fake and everyone has their own. This can lead to inhomogeneities in the systems used. Naturally, it is not very awkward when we have such two systems, but if their number grows - managing such a process can become inefficient and time-consuming over time.

The best way to avoid such problems is to consolidate systems, and along with it the creation of transparent and useful synoptic screens.

One of the clients who asked us to consolidate SCADA systems is Wodociągi Raciborskie (Waterworks in Raciborz)

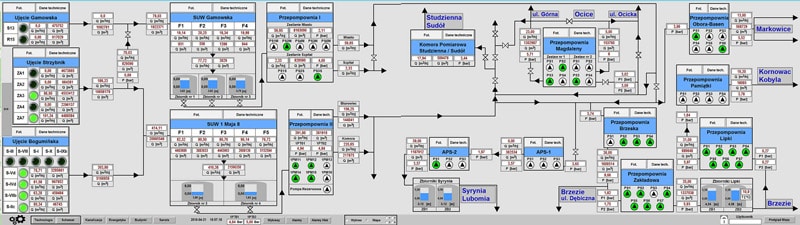

Before our engineers started their work there, there had been four independent, separate SCADA systems. Both the staff of Wodociągi Raciborskie and us had the idea of creating one common, well-connected and intuitive application that controls the processes. Creating such a system allows for a better visualization of work correlation among individual technological systems. Unifying the look of synoptics, and thus imaging data and technological parameters in a clear and transparent way, makes it possible to decide faster in crisis situations. It also drastically reduces the training time for new employees. They used to learn 4 systems, now it’s just one.

Consolidation of several systems also allows for savings – both in software and hardware.

It is worth mentioning that creating a common SCADA system (based naturally on Proficy iFIX) was also an excellent opportunity to carry out the necessary modernization in regard to security of process continuity. Along with new screens, sorting out licensing issues, there was also a system redundancy implemented (the system automatically switches between one and the other server) – thanks to which you can quickly restore the operating parameters of devices in case of a failure, and a failure of one of the computers or service work does not stop the system operation.

However, this is not the end of the changes – the variables have also been organized – the unified SCADA system connects to only one database (Proficy Historian)!

Other elements implemented and standardized as part of the work of VIX Automation engineers include: adding desktop and remote clients (Proficy Webspace), thanks to which in crisis situations key decisions can be made without being in the central control room. Our engineers also took care of new, convenient and compliant reports.

The SCADA system known from the Water Authority was also used in the Sewage Treatment Plant, thanks to which we were able to recreate the continuity of the technological scheme – from extracting water from intakes, through its distribution to individual areas of the city, to the treatment of the generated sewage.

Systems consolidation allows for better, more effective and safer work!

Watch the video that presents the history of this implementation (with English subtitles):