SCADA / HMI Systems

WHAT IS SCADA SYSTEM?

'SCADA' - one of the indispensable IT systems of modern production - is an abbreviation from Supervisory Control And Data Acquisition. This name reflects the basic functions fulfilled by the SCADA system: control of the technological process and acquisition of production data. The source of this data can be PLC controllers, sensors (all actuators or measuring devices). The collected data is interpreted by the SCADA system and in the form of synoptic screens is responsible for the process visualization. Thanks to the technological process visualized on the computer screen, the operator has a detailed view of the current situation at the plant and gains full control over the production.

IS HMI THE SAME AS SCADA?

HMI panel (Human Machine Interface) - is a communication interface that links the operator and the machine. On the HMI panel screen, the operator has access to a visualized process element that he can control. It implements the basic functions of the SCADA system, but the SCADA system is superior. What's more, SCADA has control over the entire process, and the HMI panel - usually only over a single machine (local control). Modern systems, such as the Proficy iFIX, combine both of these functions, hence the name Proficy HMI / SCADA iFIX.

ADVANCED VISUALIZATION AND CONTROL SYSTEMS

Modern HMI/SCADA system is not limited to the visualization of the production process, but also performs a number of other tasks, such as comprehensive reporting, remote, safe and ergonomic access to data via the Internet, intelligent alarm management or an intuitive interface for MES systems.

SCADA (Supervisory Control And Data Acquisition) is an IT system that performs the functions of process control, data acquisition and archiving, process visualization, as well as alarming and data reporting.

VIX Automation offer includes the process of designing and creating SCADA systems using the latest technologies, as well as the issues of modification and development of existing installations. All projects are implemented on the basis of the latest standards and tools, provided by one of the world leaders in IT solutions for production – GE Digital. In our work, we also follow the guidelines on best practices in creating user-friendly and ergonomic applications (so-called next generation SCADA).

Services we provide are performed by certified GE technical support engineers (Certified Support Professional) and our trading partners with unique knowledge and industry experience.

Central control room with a multi-monitor SCADA application

HMI / SCADA SYSTEMS – USED TECHNOLOGIES

Projects based on GE Digital Proficy software, including SCADA iFIX / Webspace and SCADA Cimplicity systems allow the use of the latest technologies, such as:

- installation reliability through full redundancy

- SCADA via www: access to data and analyzes via web browsers and mobile devices

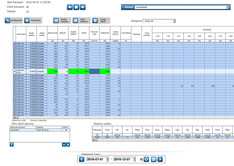

- archiving of production data in the professional industrial Proficy Historian database

- intelligent alarm management and notification (including email)

- the latest, open communication standards

- global cybersecurity standards

- compliance with the Industry 4.0 concept

SCADA SOFTWARE – EXAMPLES OF REALIZATIONS AND ACHIEVED EFFECTS

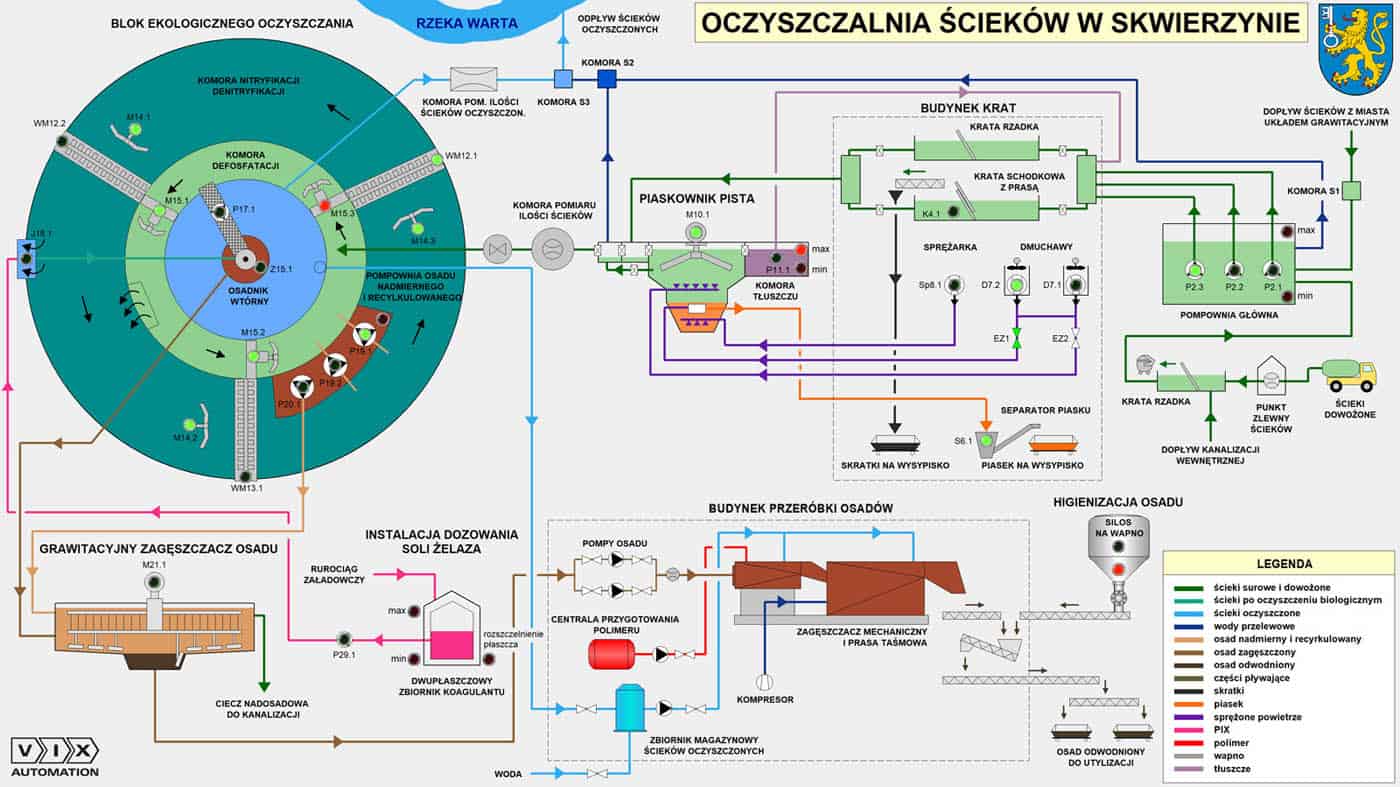

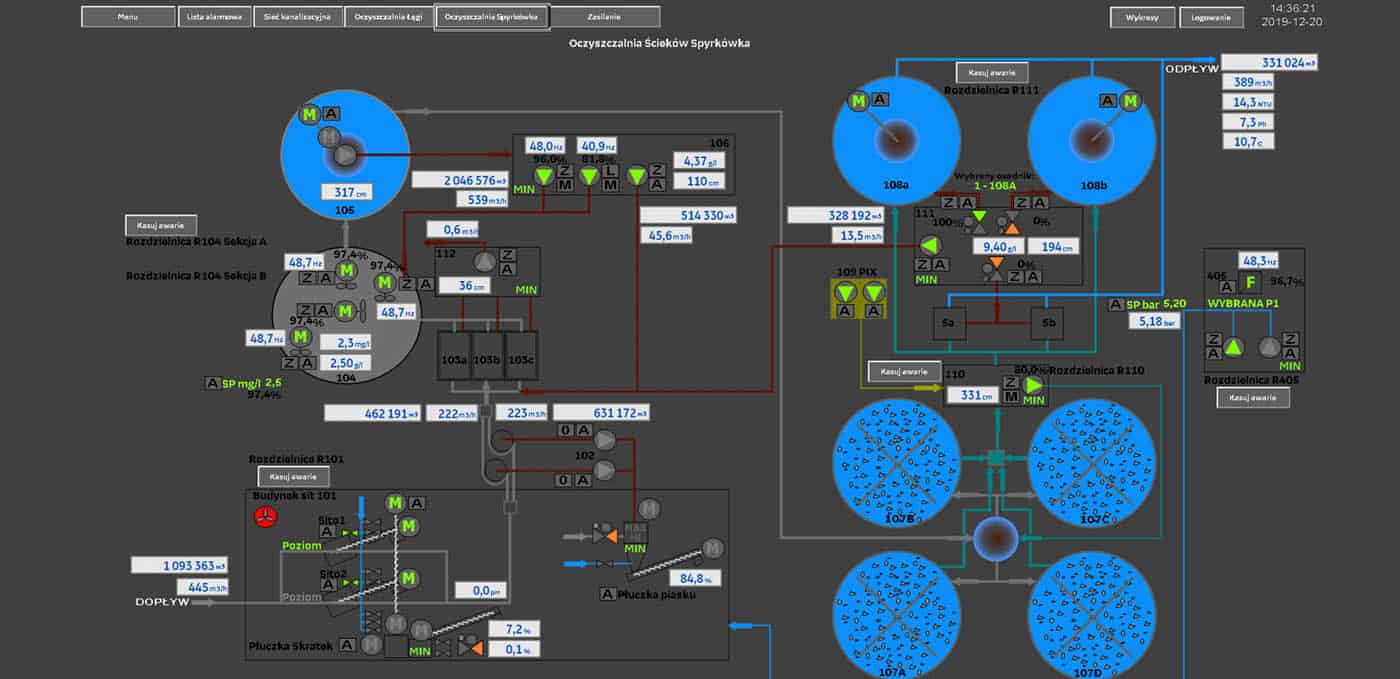

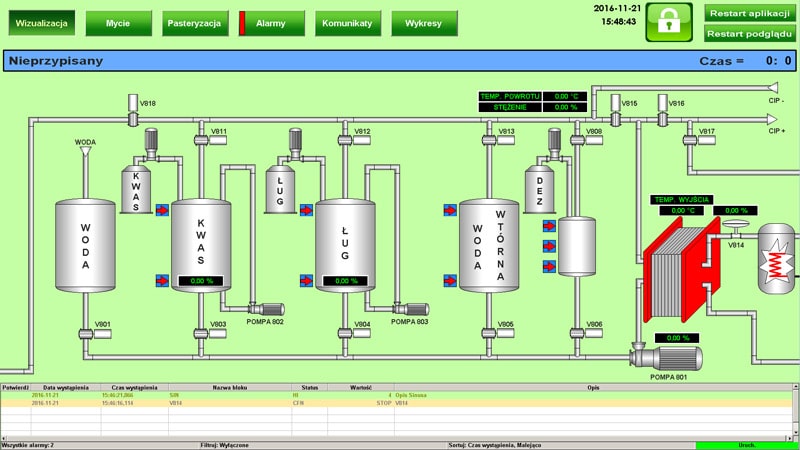

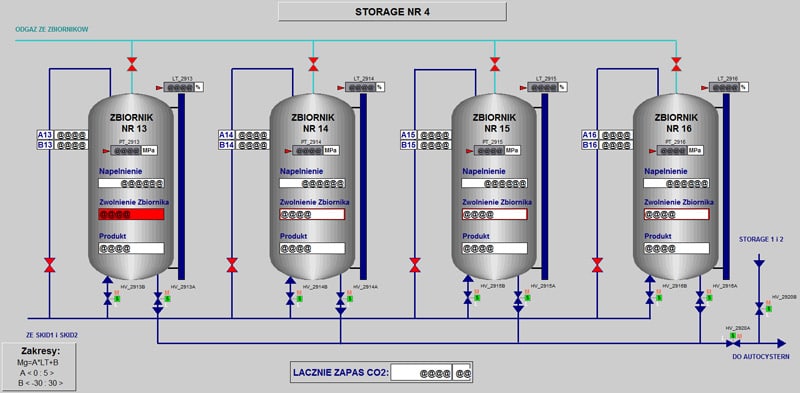

The SCADA systems we provide are used in all key industries including food & beverage, chemical industry, paper industry, water and sewage industry, heat and power plants and BMS – intelligent buildings.

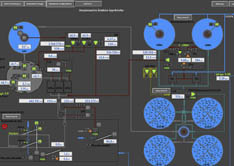

- Modernization of the SCADA system in the heat and power plant

Multi-station system based on Proficy HMI / SCADA iFIX 5.8 with server redundancy. Remote access to data with Proficy Webspace. Numerous synoptic screens using over 1000 stations. - Intelligent building system

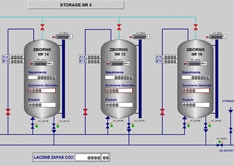

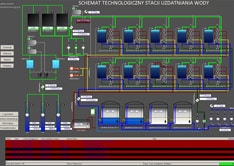

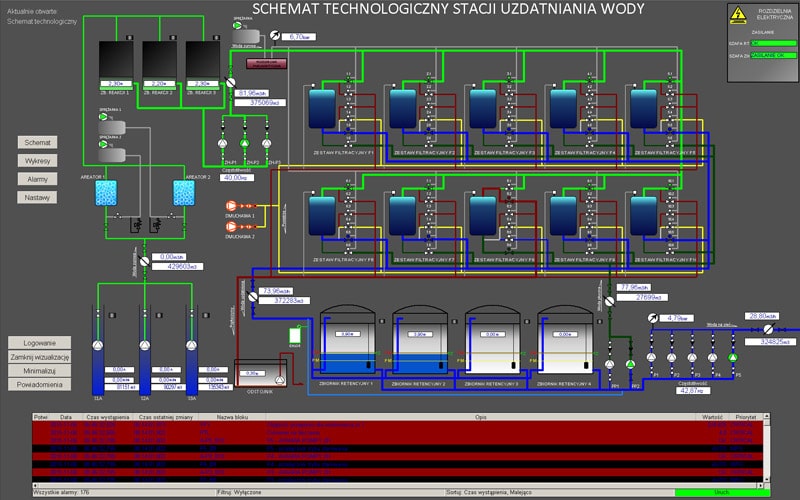

Visualization of the air conditioning system in two multi-storey buildings based on Proficy Cimplicity 9.0. About 25 synoptic screens using over 2000 variables. - Water treatment station management system

Water treatment station visualization system using Proficy HMI / SCADA iFIX 5.5. Support for over a dozen remote sources, along with an intelligent alarm system (using e-mails and text messages) - Cheese production process visualization system

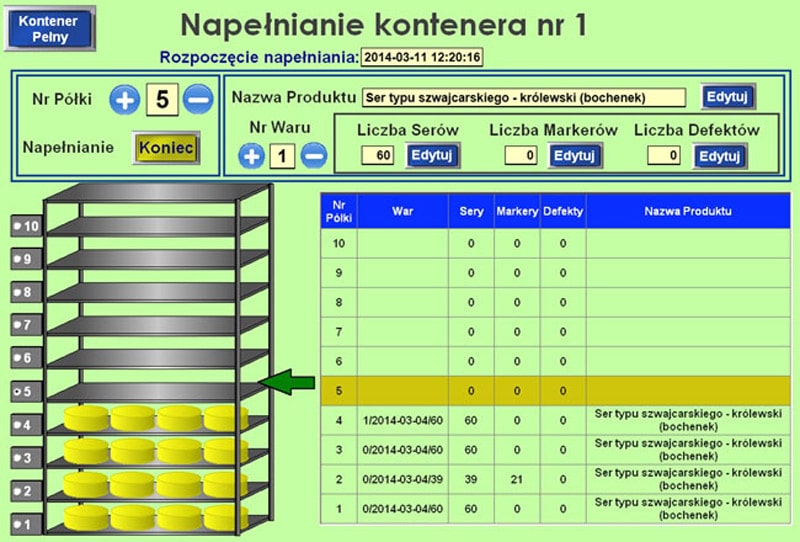

Visualization of the complete hard cheese production process using the Proficy HMI / SCADA iFIX system. The system consist of approximately 20 Proficy iFIX servers and stations as well as the Proficy Historian central corporate data repository.

SCADA SYSTEM: THE BASIS FOR ADVANCED PRODUCTION SOLUTIONS

Visualization systems are also the basis for implementing more advanced IT tools for production, fox example:

- media balancing systems

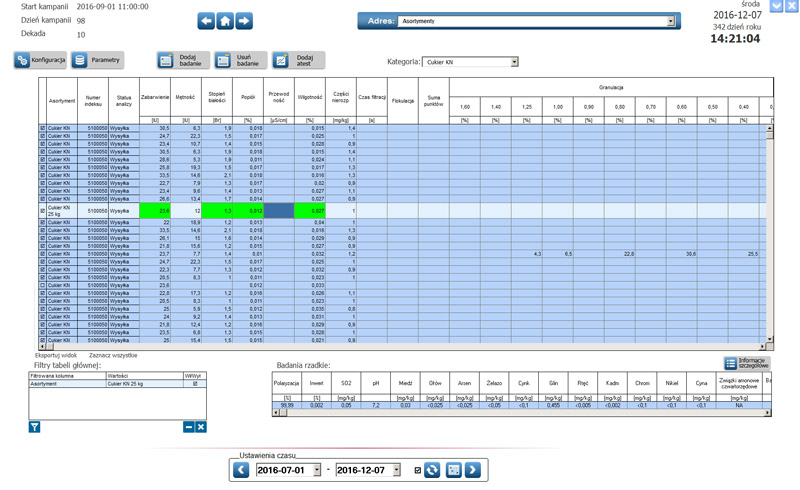

- quality control systems

- industry-specific solutions (e.g. laboratory journal and approval system)

- supervision over the implementation of HACCP procedures

- systems using the visualization of signals on Google maps (e.g. vehicle tracking) and many others

SCADA SYSTEM IMPLEMENTATION WITH VIX AUTOMATION

When is it worth using the services of VIX Automation or one of the Certified Partners of GE Digital?

- Are you planning to modernize your current SCADA system as the application runs on outdated hardware and unsupported operating systems?

We will help you to update it efficiently – we will advise you in choosing the right hardware and operating system to run it. This is also a good time to rethink the system architecture – e.g. adding remote access. - The application does not cover all the required areas and machines at the plant?

We will advise you on how to effectively and without disruptions in the current production expand the installation. - Are you missing relevant reports or access to historical data?

We will audit the application, listen to your needs and suggest how to meet them. We will propose the right tools or a pilot solution to make sure you are getting exactly what you want. - Are you looking for a trustworthy partner in the design and implementation of a SCADA system?

Put your trust in our and our partners’ years of experience in all industries and global IT leader for industry – GE Digital.

Find out more about VIX Automation implementation services >>