OEE analysis for the operations optimization

In industrial companies and production plants, the issue of process optimization is one of the key issues for improving the efficiency and minimizing the company’s operating costs. Management science provides many tools to optimize activities – including the entire group of lean management tools. Modern lean management tools are based on IT solutions that are being implemented to an increasing extent. The flagship example of this type of technology is automatic OEE analysis.

What is OEE analysis?

OEE (Overall Equipment Effectiveness) is an indicator that determines the so-called total equipment efficiency – effective use of the main machines and devices used in the production plant. Manual OEE analysis is very time-consuming, with a multiple observations of functioning of the machine park individual elements. OEE analisys allows you to find out the reasons for downtime, analyze the working time of machines and possible equipment defects. An essential element of proper OEE analysis is the feedback, i.e. reporting key parameters of the machine park. Modern automatic OEE analysis allows for significant simplification and optimization of this process.

Implementation of automatic OEE analysis

The use of modern VIX Automation solutions allows for complex and error-free OEE calculations. The scheme of implementation is as follows:

- performing an audit and creating concept for OEE solutions;

- preparation of the machine park (including the production line) for OEE measurement;

- taking measurements and collecting information in databases;

- construction of downtime trees and recommendation of actions and best practices;

- analysis and interpretation of the obtained results.

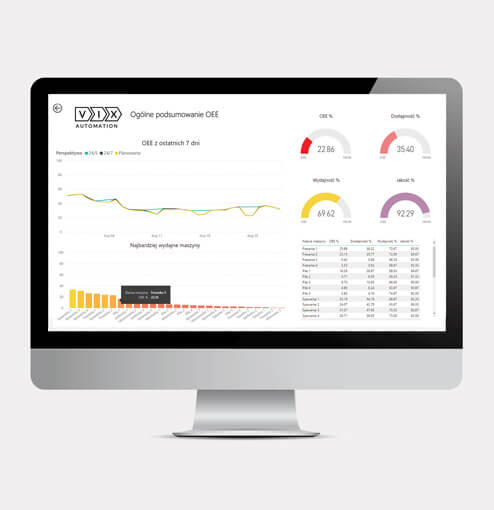

The most important functionalities of OEE systems

From the point of view of a thorough analysis of production processes, it is necessary to calculate the OEE indicator determined in various contexts, such as: shift, week, month, product, order. The best systems allow to determine the level of the current and cumulative OEE indicator, analyze and categorize downtime, etc. In the final reporting, it is important that the system accurately presents the individual elements of the indicator: availability, performance and quality. VIX Automation IT systems also provides very good visualization of individual elements of the OEE indicator.