Case Study – control and visualization system in the Ametist paper mill

In VIX Automation we have always highly valued cooperation with automation system integrators. Our network of trusted partners includes both large system integration organizations and smaller technical support companies. One of the partners with whom we have managed to develop good, long-term relationship is Palmatik Automatyka Przemysłowa. Therefore, we are pleased to present the case story of the Proficy software implementation, carried out by this partner in the Ukrainian Ametist paper mill, which suffered during the Russian invasion.

About the implementation

ABOUT AMETIST

The Ametist company was born from a simple idea of friends who established it in 1999 in response to the difficult situation on the Ukrainian market at that time – there was a shortage even of toilet paper in stores. After gaining the necessary experience in neighboring European countries, the decision was made to purchase the first production line in Poland. Since then, the company has been constantly developing, increasing quality and product range.

Paper machine at the Amestit plant

Nowadays, Ametist supplies papers for everyday use (toilet paper, paper towels, napkins) and for the HoReCa industry, as well as waste paper and cellulose paper to all regions of Ukraine and Eastern Europe, serving approximately 15% of the domestic market and cooperating with a network of over 200 partners.

Unfortunately, during the Russian invasion of Ukraine, the Ametist company suffered greatly – as a result of the bombing of Chernihiv, over 70% of the company was destroyed, including production lines, warehouses with raw materials and finished production, with a total area of over 5,000 square meters.

With the help of Polish partners and well-coordinated team work, it was possible to partially restore the lost production capacity and jobs. The work is ongoing, we are creating new plans for the company's development, we have plenty of ideas and the willingness to implement them.

Valeriy Radchenko

Director, Ametist

A paper machine after destruction and after the reconstruction of the plant

PURPOSE OF IMPLEMENTATION

The implementation of a SCADA system based on Proficy software was to ensure:

- supervision of the hygiene paper production process on a new paper machine

- control of the steam condensate system of a paper machine

- archiving and insight into historical production data.

SCOPE OF IMPLEMENTATION

The implementation at Ametist included two stages. The first was the modernization and implementation of a control system with archiving. The second stage was the reconstruction of the installation after the bombing damage. Before the implementation, the company had an old, small paper machine with a pulp preparation process without automation systems, visualization and without historical data acquisition.

The system was implemented by Palmatik Automatyka Przemysłowa – system integrator specializing in the paper industry. The company successfully co-created and implemented the production management system at Głuchołaskie Zakłady Papiernicze, which was the inspiration for Ametist.

Control room at the Ametist paper mill

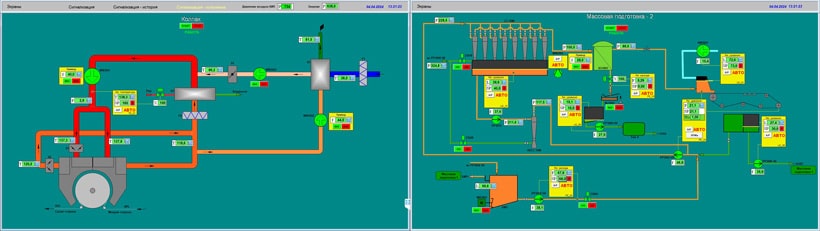

Proficy HMI/SCADA iFIX was used to enable operators to:

- conducting the process of preparing pulp for the production of hygiene papers

- control of the steam condensate system of a paper machine

- supervision of the main drives of the machine

The use of the Proficy Historian industrial database allows for:

- collecting historical process data

- quick presentation of data using charts.

The hardware layer includes PLC controllers, operator panels and frequency converters, as well as a router enabling remote access to the system.

SCADA iFIX system in Ametist

Proficy software was chosen due to good opinions and user satisfaction from previous projects at Głuchołaskie Zakłady Papiernicze and very good technical support of the distributor - VIX Automation.

Janusz Paliga, integrator

Palmatik Automatyka Przemysłowa

ABOUT INTEGRATOR

The activities of PALMATIK Industrial Automation focus mainly on the automation of industrial processes and the design of production control systems. The company was established in 2021 by Janusz Paliga, but he has been associated with industrial automation for over 25 years. He specializes in the following industries: paper, heating and sewage treatment plants.

Implementation effects

The use of Proficy HMI/SCADA iFIX allowed for more efficient conduct of the complex paper production process, which meets quality requirements while being economically effective.

The implementation of Proficy Historian allows for process analysis and optimization.